Introduction

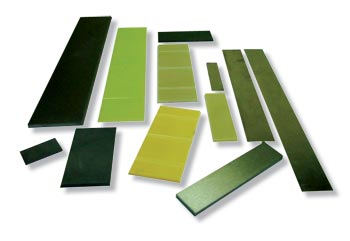

Carbon vanes are essential components used in various industries, including automotive, aerospace, and manufacturing. They are commonly used in vacuum pumps, compressors, and rotary machines. Carbon vanes are known for their durability, low friction, and excellent heat resistance. In this article, we will explore the different types of carbon vanes and their applications.

1. Carbon Graphite Vanes

Carbon graphite vanes are the most common type of carbon vanes. They are made from a combination of carbon and graphite materials, which provide excellent self-lubricating properties. These vanes are suitable for high-speed applications and can withstand high temperatures. Carbon graphite vanes are commonly used in rotary vane pumps, vacuum pumps, and compressors.

2. Resin-Bonded Carbon Vanes

Resin-bonded carbon vanes are made by impregnating carbon fibers with a resin binder. This type of vane offers good chemical resistance and high mechanical strength. Resin-bonded carbon vanes are commonly used in chemical processing, where they can withstand corrosive environments and high pressures.

3. Metal-Bonded Carbon Vanes

Metal-bonded carbon vanes are made by combining carbon fibers with a metal matrix, such as copper or bronze. This type of vane offers excellent thermal conductivity and high wear resistance. Metal-bonded carbon vanes are commonly used in high-temperature applications, such as aerospace and automotive industries.

Conclusion

Carbon vanes come in various types, each with its unique properties and applications. Whether it is carbon graphite, resin-bonded, or metal-bonded, choosing the right type of carbon vane is crucial for ensuring optimal performance and longevity in different industrial processes.